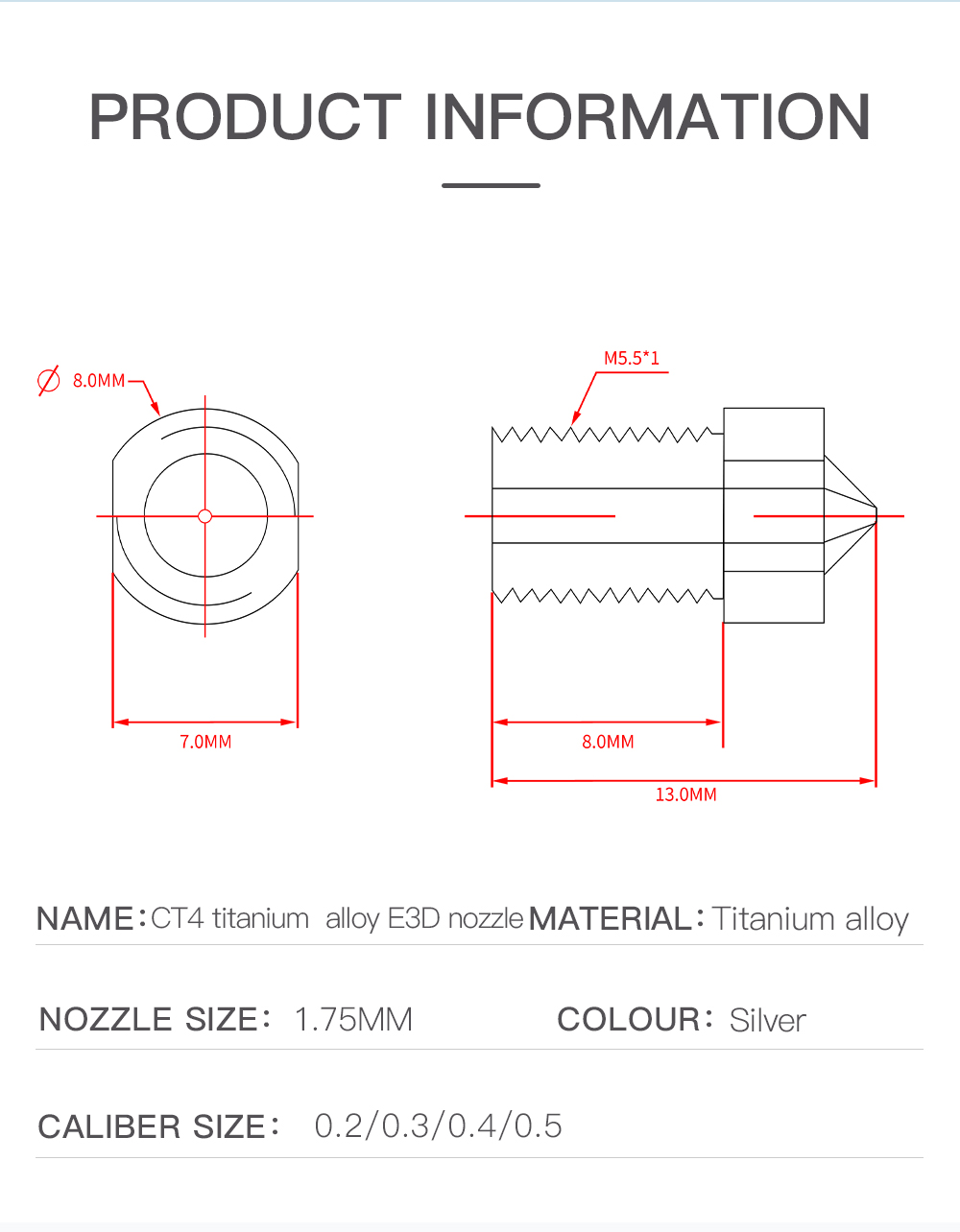

CT4 Titanium E3d Nozzles– V6-1.75mm-0.2mm\0.3mm\0.4mm\0.5mm

₹329.00 – ₹353.00

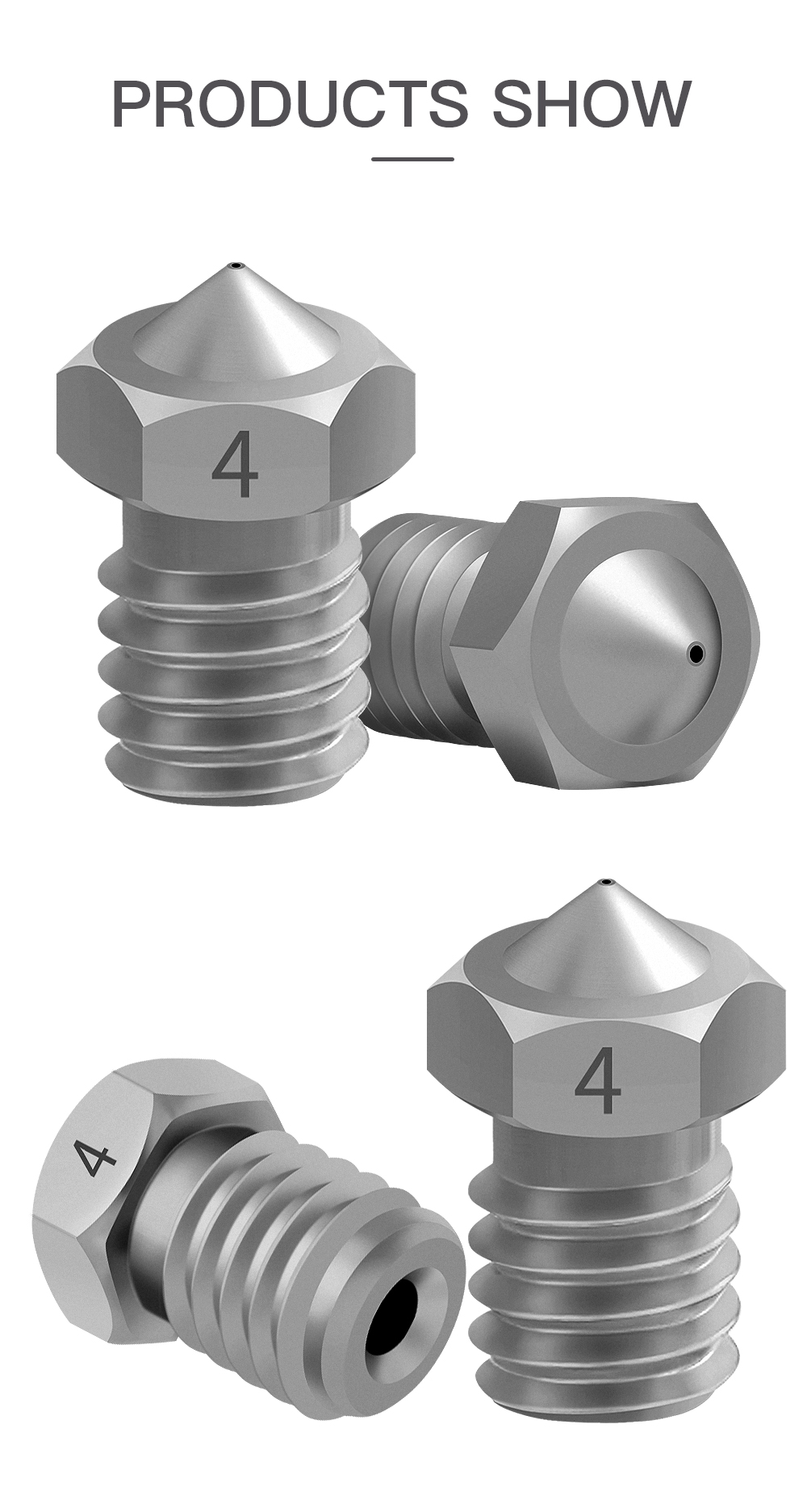

• Our CT4 Titanium E3d nozzles are precision-crafted to fit the E3D series, and are perfect for any project that requires high-quality printing.

• The high quality Nozzle size: 0.4mm, M6 thread for 1.75mm filament use

• Less build up

• Improved first layer reliability

• Smooth top solid layers with a glassy like finish

• Easier nozzle cleaning

Mechblock Shopping Event

Hurry and get discounts on all Mechblock Products up to Rs.1000

Coupon code: MECHBLOCK

Description

Our ct4 titanium e3d nozzle are precision-crafted to fit the E3D series, and are perfect for any project that requires high-quality printing. The titanium alloy is harder than stainless steel, making the nozzle much more wear-resistant and increasing its lifespan. We’ve added a new nozzle length to our printer – the 0.8mm will create finer details with any 3mm filament, perfect for intricate prints. Our TC4 alloy has a strength of 1,012 MPa, density of 4.4×103, specific strength of 23.5, and the specific strength of alloy steel is less than 18. Despite its low thermal conductivity, titanium alloy is still a popular choice for engineering projects. Its low weight and corrosion resistance are major benefits, and the metal still retains some heat-transfer capabilities despite its low rating.

The nozzle is made of titanium alloy, a high-quality material that is known for its stability performance. The titanium alloy is also very light and durable, which makes it a perfect choice for the print something hard.

Superiority:

1. High strength and hardness alloy, precision-made and designed for 3D printers. Made of extremely hard and wear-resistant material, stronger than steel.

2. Good corrosion resistance and strength retention. Suitable for all storage temperatures, from -30C to +120C. Extensive temperature range. Can withstand prolonged high temperatures and low temperatures

3. High heat resistance . It can withstand a temperature of at-least 200C, and its use for hot extrusion greatly improved the efficiency of filament extrusion

4. Wear resistance . The alloy is not only more wear-resistant than other alloys, but also not very easily worn. It is significantly better in wear resistance than carbon steel,

5. Finer processing . It can be finished with different processing methods, such as annealing, tempering, and coating. It has excellent mechanical properties and ease of finishing

Additional information

| Weight | .010 kg |

|---|---|

| Dimensions | 5 × 5 × 4 cm |

| E3D Nozzle SIZE |

0.2mm ,0.3mm ,0.4mm ,0.5mm |

| HSN Code | |

| Condition |

54 reviews for CT4 Titanium E3d Nozzles– V6-1.75mm-0.2mm\0.3mm\0.4mm\0.5mm

Clear filtersMore Products

Metal Dual V Wheel Assembled

In stock

Aluminium Round Spacers

In stock

Aluminium Round Spacers

In stock

Carbide 10pcs PCB Drill Bit Set

In stock

C-Beam Linear Actuator Kit with motor Assembled

In stock

XTOOL

XTOOL

ATOMSTACK

ATOMSTACK

SCULPFUN

SCULPFUN

ORTUR

ORTUR

TWOTREES

TWOTREES

Diode Laser Machines

Diode Laser Machines

Laser Modules

Laser Modules

Laser Machine Accessories

Laser Machine Accessories

P Series

P Series

S Series

S Series

F Series

F Series

M Series

M Series

D Series

D Series

xTool SafetyPro™ AP2 Air Purifier

xTool SafetyPro™ AP2 Air Purifier

Rotary Roller

Rotary Roller

Honeycomb

Honeycomb

Extension Kits

Extension Kits

Towers Support Shelf Block

Towers Support Shelf Block

SCULPFUN SF-A9

SCULPFUN SF-A9

SCULPFUN S10

SCULPFUN S10

SCULPFUN S9

SCULPFUN S9

Gantry Carts Kits

Gantry Carts Kits

Wheels

Wheels

Salina Parihar (verified owner) –

Quite easy to use, nice design, surely will buy again

ParvatiJindal (verified owner) –

Been using a lot of items, this one is obviously the best

Vijay Sohra –

Superb Quality

Mani Shankar (verified owner) –

The item and the design are very cool. Also the support is amazing, they always help you with any detail that you have.

Store manager mechblock –

Thank you so much for your 5-star review! We will share this with the store team to let them know to keep up the amazing work.

Raman amma (verified owner) –

I rarely leave a comment, but this item is beyond worth it! Gotta let you guys know!

Store manager mechblock –

Thank you for your kind review! It’s a big encouragement to us!

Shahid Ansari (verified owner) –

Just love the design and the customer support is the nicest.

Store manager mechblock –

Your kind words just made our days! Thank you so much!

Vijay (verified owner) –

I want to say thanks to the support team for helping with my continuously silly questions, you’re the best!

Bishvajit Tayal (verified owner) –

Quite easy to use, nice design, surely will buy again

Dhirendra Soni (verified owner) –

It’s far better than those similar products, while the price is still acceptable.

Parvathi Gupta (verified owner) –

Great item! It provides too many things compared to its price charged.

Prahlad Bisnoi (verified owner) –

Been using a lot of items, this one is obviously the best

Gulshan Apte (verified owner) –

I want to say thanks to the support team for helping with my continuously silly questions, you’re the best!

Jamila Ansari (verified owner) –

This is the coolest thing I’ve found on here! Will keep using your products in the future!

Anila Antony (verified owner) –

I am a beginner and this laser engraver is equipped with everything I need. I USED GBRL SOFTWARE WITH A MAC SYSTEM AND THE CONNECTION WAS EASY. When cutting wooden blocks, I find it as easy as carving planks. And the effect is not bad, it is a good laser machine.

Kabita Kaushik (verified owner) –

Equipped with detailed assembly instructions, making assembly very easy to complete in 30 minutes. This laser machine is also suitable for inexperienced users. I am very satisfied!

Kunalv Dwivedi (verified owner) –

I did find that there was some smell while using it and found it would be better to use this engraver in a ventilated area. I think it should be necessary to buy another air assist to direct the airflow to the outside, the effect will be better!

Kamalesh Jain (verified owner) –

This machine is the best I’ve ever seen, great quality, beautiful packaging, top notch engraving and cutting, thanks MechBlock!

Anima gandhi (verified owner) –

Very nice machine. With Lightburn very easy to work with it.

Smriti Bansal (verified owner) –

Easy assembly, directions were very easy to follow. Download light burn and easy to setup. Tested it out and did my Sasquatch for my cutting boards.

Laksmi Iyer (verified owner) –

Very fast shipping, arrived quicker than I thought, everything in perfect condition, no damage and complete with accessories. I have tested the machine and everything works fine. This machine is really nice, I love it. I will recommend it to my friends!

Mahesabhai Grover (verified owner) –

The machine came a few days earlier than stated. Very well packaged and the installation also went smoothly. After I executed the commands and calibrated the device, everything went as it should and the machine correctly found the position of the laser head. I hope that it will remain stable in the future and that the values will remain as it is calibrated. Everything works correctly I am really impressed with the performance of the machine and the results of the laser work.

Rohini Raghav (verified owner) –

I am very satisfied with the engraving machine, I am a beginner and would like to familiarize myself with this equipment. It definitely fits the purpose. Looking forward to the effect!

Dipali Kaushik (verified owner) –

I did find that there was some smell while using it and found it would be better to use this engraver in a ventilated area. I think it should be necessary to buy another air assist to direct the airflow to the outside, the effect will be better!

Kunalv Pandey (verified owner) –

Fast shipping and perfectly packaged. The laser machine is of high quality, operated according to the instructions, even beginners can master it quickly, everything is as described, it is great.

Banhi Gupta (verified owner) –

This machine is the best I’ve ever seen, great quality, beautiful packaging, top notch engraving and cutting, thanks MechBlock!

Dularee Apte (verified owner) –

Perfect machine, well packaged, great engraving and cutting, worth buying!

Banjeet Patel (verified owner) –

Ashvaghosha Verma (verified owner) –

Easy assembly, directions were very easy to follow. Download light burn and easy to setup. Tested it out and did my Sasquatch for my cutting boards.

Amitabh Goel (verified owner) –

Equipped with detailed assembly instructions, making assembly very easy to complete in 30 minutes. This laser machine is also suitable for inexperienced users. I am very satisfied!

Aswad Chaturvedi (verified owner) –

Very nice machine. With Lightburn very easy to work with it.

Yashoda Patil (verified owner) –

I am a beginner and this laser engraver is equipped with everything I need. I USED GBRL SOFTWARE WITH A MAC SYSTEM AND THE CONNECTION WAS EASY. When cutting wooden blocks, I find it as easy as carving planks. And the effect is not bad, it is a good laser machine.

Rachanna Bansal (verified owner) –

Nayantara Jaiswal (verified owner) –

Very fast shipping, arrived quicker than I thought, everything in perfect condition, no damage and complete with accessories. I have tested the machine and everything works fine. This machine is really nice, I love it. I will recommend it to my friends!

Daya Shankar (verified owner) –

The machine came a few days earlier than stated. Very well packaged and the installation also went smoothly. After I executed the commands and calibrated the device, everything went as it should and the machine correctly found the position of the laser head. I hope that it will remain stable in the future and that the values will remain as it is calibrated. Everything works correctly I am really impressed with the performance of the machine and the results of the laser work.

Mana Bansal (verified owner) –

Fast shipping and perfectly packaged. The laser machine is of high quality, operated according to the instructions, even beginners can master it quickly, everything is as described, it is great.

Shresht Kapoor (verified owner) –

I am very satisfied with the engraving machine, I am a beginner and would like to familiarize myself with this equipment. It definitely fits the purpose. Looking forward to the effect!

Gautam Ghosh (verified owner) –

Perfect machine, well packaged, great engraving and cutting, worth buying!

Chandrashekhar Singh (verified owner) –

I am very satisfied with the engraving machine, I am a beginner and would like to familiarize myself with this equipment. It definitely fits the purpose. Looking forward to the effect!

Mary Philips (verified owner) –

Easy assembly, directions were very easy to follow. Download light burn and easy to setup. Tested it out and did my Sasquatch for my cutting boards.

Dhruv Chadha (verified owner) –

Very fast shipping, arrived quicker than I thought, everything in perfect condition, no damage and complete with accessories. I have tested the machine and everything works fine. This machine is really nice, I love it. I will recommend it to my friends!

Satish Banerjee (verified owner) –

The machine came a few days earlier than stated. Very well packaged and the installation also went smoothly. After I executed the commands and calibrated the device, everything went as it should and the machine correctly found the position of the laser head. I hope that it will remain stable in the future and that the values will remain as it is calibrated. Everything works correctly I am really impressed with the performance of the machine and the results of the laser work.

SundariSharma (verified owner) –

I did find that there was some smell while using it and found it would be better to use this engraver in a ventilated area. I think it should be necessary to buy another air assist to direct the airflow to the outside, the effect will be better!

Atul Jha (verified owner) –

This machine is the best I’ve ever seen, great quality, beautiful packaging, top notch engraving and cutting, thanks MechBlock!

Saroj Kapoor (verified owner) –

Fast shipping and perfectly packaged. The laser machine is of high quality, operated according to the instructions, even beginners can master it quickly, everything is as described, it is great.

Gangadhar Jain (verified owner) –

Very nice machine. With Lightburn very easy to work with it.

Shamim Ansari (verified owner) –

I am a beginner and this laser engraver is equipped with everything I need. I USED GBRL SOFTWARE WITH A MAC SYSTEM AND THE CONNECTION WAS EASY. When cutting wooden blocks, I find it as easy as carving planks. And the effect is not bad, it is a good laser machine.

Sarada Ben (verified owner) –

Equipped with detailed assembly instructions, making assembly very easy to complete in 30 minutes. This laser machine is also suitable for inexperienced users. I am very satisfied!

Kumar Shankar (verified owner) –

Babubhai Sharma (verified owner) –

Bibi iyenger (verified owner) –