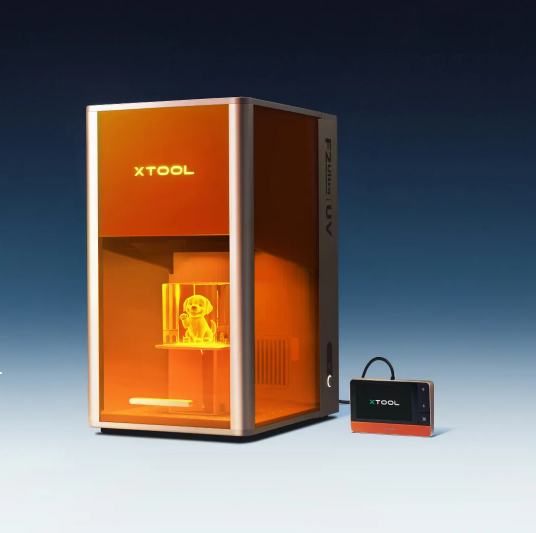

Why UV Lasers Stand Out

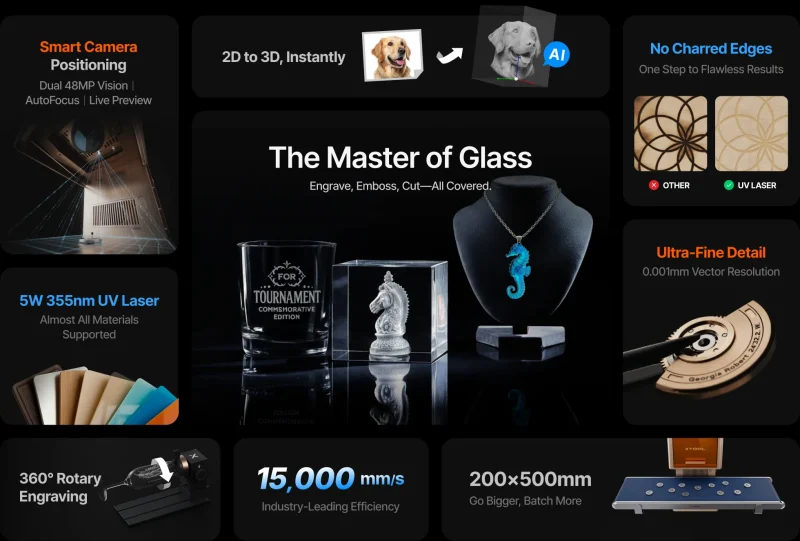

For years, UV technology has been a cornerstone of fields like medicine and electronics, where precision is paramount. With an ultra-short 355 nm wavelength, the UV laser achieves micron-level detail and flawless finishes without scorching. Excelling where others fall short, it works effortlessly on glass, plastic, textiles, acrylic, and more.

Mastering Glass, Inside and Out

UV laser is a leading technology for precise glass processing. From 3D inner engraving to embossing, cutting, rotary engraving, and batch processing—each technique flawlessly transforms glass into high-quality, long-lasting masterpieces.

UV Power, Unmatched Performance

No Dark Edge, One Step to Perfection

The UV laser uses high photon energy to break molecular bonds directly with a minimal heat zone—no burn marks, no charring—preserving your material’s integrity. No messy pre-coating or post-polishing, only clean, precise, premium results. That’s the magic of cold processing.

Micron Precision, Museum-Grade Detail

The shorter the wavelength, the smaller the laser spot—UV lasers set a new standard for micron-level detail. With a spot size of less than 10 μm, UV laser engraving is over 100× smaller than CO2 lasers, ensuring every line is sharp, flawless, and precise down to the finest detail.

The Smartest Experience Ever Built

2D to 3D to Masterpieces, Incredibly Easy

Think 3D inner engraving is complex? Think again. Powered by xTool’s professional AI agent, we offer the simplest all-in-one solution—turn text or 2D into 3D with one click and enjoy stunning results in minutes.

Dual 48MP Cameras. See It. Get It.

The industry’s first dual-camera UV laser system. Two cameras handle automatic positioning and focusing, achieving 0.2 mm accuracy—60% more precise than single-camera systems. Every process is consistently effortless, and every detail is exactly as you imagined.

Unlock More Materials. Go Beyond Limits.

As the ultimate laser for almost all materials, UV laser does what others can’t— capturing fine detail even on crystal, ceramic, acrylic, agate, and more, offering the widest material compatibility ever. With UV lasers, the only limit is imagination.

How Does UV Laser Work

The UV laser uses photochemical ablation, often called “cold marking.” The short, high-energy UV photons carry enough energy to directly break the molecular bonds on the material’s surface without generating significant heat. UV laser is an ideal option for delicate materials that can’t be exposed to the immense heat produced by IR or blue lasers.

CO2 and fiber lasers rely on heat. They hit the material, cause rapid temperature rise (melting or vaporization), and the resulting mark is a product of this thermal effect (e.g., charring wood, oxidizing metal, melting plastic). This creates a Heat-Affected Zone (HAZ), leading to micro-cracks in glass or warping in sensitive plastics.

UV Laser vs. Traditional Laser

There are three fundamental aspects of laser engraving to consider when evaluating the differences between traditional and UV laser tools: Material compatibility, mechanism, and wavelength.

As mentioned above, UV laser marking is a cold process, which is the key difference. Engraving involves ablation, the wearing away of surface spots, which traditional laser tools accomplish through hot marking. With UV laser tools, the ablation process is photochemical. When comparing the wavelength, fiber and CO2 lasers feature long emissions up to 10,600 nanometers (nm). UV lasers emit wavelengths around 355 nm. Whereas fiber lasers are used to mark metal and hard acrylics, UV lasers can mark with high resolution on ceramics, film, glass, and a wider range of heat-sensitive materials.

The UV Laser Superpower

Accessibility and versatility are the main benefits of UV laser engraving. The cold process features zero heat damage; it eliminates the risks of melting, cracking, or material distortion. You can use UV laser tools for ultra-fine precision engraving, like on micro-electronic components. You also get a higher versatility of high-contrast permanent marking on many materials.

FAQ

Why only 5W? Is it enough?

5W is the optimal balance for desktop size, cost, and high-precision engraving.

UV lasers have a short wavelength and high-energy photons, which directly break molecular bonds with very little heat. This “cold processing” delivers much higher energy density and precision than traditional heat-based lasers.

That’s why 5W is considered the golden power level for desktop UV systems. Even for demanding tasks like 3D engraving inside glass, the F2 Ultra UV typically uses only around 60% of its power—leaving plenty of performance headroom.

Automation: Auto Streamline™ Conveyor, Pedal/Button Switch

Safety & Purification: Fire Safety Set, Safetypro™ AP2 Purifier, Safetypro™ IF2 Inline Fan.

Can F2 Ultra UV and F2 Ultra swap field lenses?

Absolutely not. Please note that F2 Ultra UV and F2 Ultra are not the same machine. They use different light sources and different interfaces, so their field lenses are not interchangeable.

The key difference: They are two machines with completely different “engines.” They share the “F2 Ultra” flagship series name—indicating they are both high-end galvanometer systems—but they are designed for entirely different materials and applications.

Reviews

Clear filtersThere are no reviews yet.