₹239.00 – ₹249.00Price range: ₹239.00 through ₹249.00

Durable and practical.

Ground roughness and overall fine polish.

Special angled slots increase rigidity.

Protects tool holder from contaminants.

We added you to this product's waitlist and we'll send you an email when the product is available.

Leave WaitlistThis product is currently sold out.

No worries! Enter your email, and we'll let you know as soon as it's back in stock.

Mechblock Shopping Event

Hurry and get discounts on all Mechblock Products up to Rs.1000

Coupon code: MECHBLOCK

Description

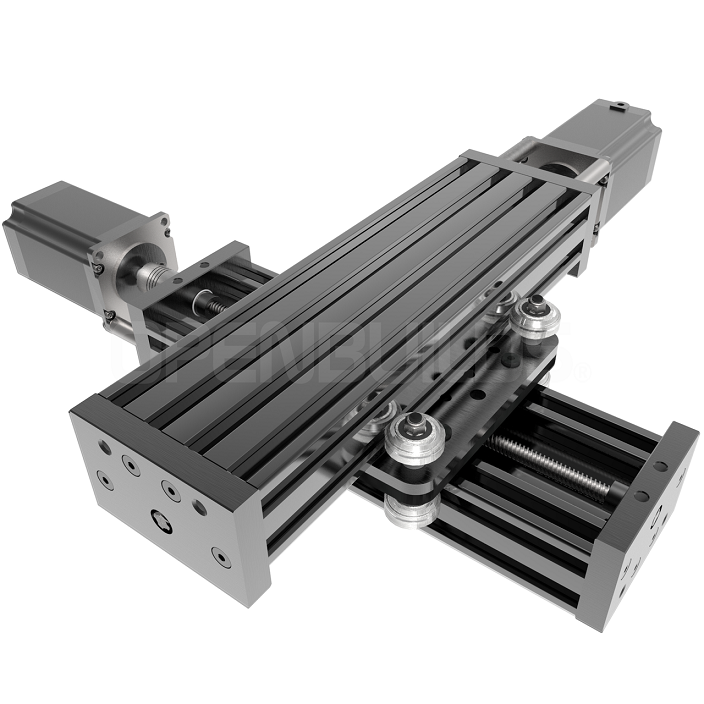

Function: The ER16 collet is a precision tool holder designed to securely hold cutting tools, such as end mills or drills, in CNC machines. It provides a strong and concentric grip on the tool, ensuring stability and accuracy during machining operations.

Function: The ER16 collet is a precision tool holder designed to securely hold cutting tools, such as end mills or drills, in CNC machines. It provides a strong and concentric grip on the tool, ensuring stability and accuracy during machining operations.

Size: ER16 collets are available in various sizes, typically denoted as ER16 followed by a number indicating the collet size. For example, ER16-1/8″ refers to an ER16 collet with a 1/8-inch clamping capacity.

Clamping Range: The clamping range of an ER16 collet specifies the range of tool diameters it can accommodate. ER16 collets can typically hold tools with diameters ranging from a few millimeters to around 10mm or more, depending on the specific collet size.

Application: ER16 collets are widely used in CNC engraving machines, milling machines, and similar machining applications. They are known for their accuracy, reliability, and versatility in holding a variety of tool sizes.

Collet Nut: To secure the tool in the collet, an ER16 collet nut is used. The nut is tightened to compress the collet, gripping the tool firmly.

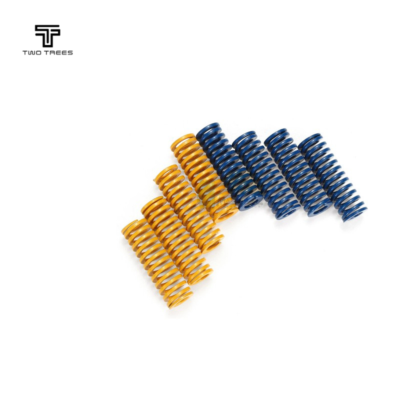

Material: ER16 collets are commonly made of high-quality spring steel or other materials that provide durability and resilience.

ER16 collets are designed for high accuracy and concentricity, which is essential for achieving precise engraving results.

- The inner bore processing by high-precision grinding according to DIN standards.

- Having tension and compression functions, brilliant and changeable.

- ER16 Collets (1,1.5,2,2.5,3,3.175,3.5,4,4.5,5,5.5,6,6.35,6.5,7,7.5,8,8.5,9,9.5,10,1/4,1/8)

- Use the high carbon bearing steel, heat treated-rigidity is HRC 48°-50°

- The inner bore processing by high-precision grinding according to DIN standards.

- Use for clamping screw tap, drill, milling cutter, reamer, and so on.

- Having tension and compression functions, brilliant and changeable.

NOTE: When using ER16 collets, it’s essential to choose the correct collet size for the tool diameter you are using.

Additional information

| Brand | |

|---|---|

| Condition | |

| HSN Code | |

| Size | , , , , , , , , , , , , , , , , , , , , |

43 reviews for Twotrees ER16 Spring Collet Set CNC Chuck

Clear filtersMore Products

4*4 Matrix Keypad Keyboard Module

In stock

C-Beam XLarge X/Y Table Bundle

In stock

C-Beam Linear Actuator Kit with motor Assembled

In stock

Twotrees ER20 COLLET for CNC Engraving Machine – 8.5mm

In stock

Nylon Plastic Pan Head Cross Round Screw

In stock

Frodrick the Frog Toilet Paper Dispenser-1 pc – Light green

In stock

XTOOL

XTOOL

ATOMSTACK

ATOMSTACK

SCULPFUN

SCULPFUN

ORTUR

ORTUR

TWOTREES

TWOTREES

Diode Laser Machines

Diode Laser Machines

Laser Modules

Laser Modules

Laser Machine Accessories

Laser Machine Accessories

P Series

P Series

S Series

S Series

F Series

F Series

M Series

M Series

Apparel Printer

Apparel Printer

MetalFab

MetalFab

xTool SafetyPro™ AP2 Air Purifier

xTool SafetyPro™ AP2 Air Purifier

Rotary Roller

Rotary Roller

Honeycomb

Honeycomb

Extension Kits

Extension Kits

Towers Support Shelf Block

Towers Support Shelf Block

iCube Series

iCube Series

SCULPFUN S10

SCULPFUN S10

SCULPFUN S9

SCULPFUN S9

Gantry Carts Kits

Gantry Carts Kits

Wheels

Wheels

Sona Goel (verified owner) –

Fast shipping and perfectly packaged. The laser machine is of high quality, operated according to the instructions, even beginners can master it quickly, everything is as described, it is great.

Bharat Daggar (verified owner) –

Shaan Goel (verified owner) –

Ishana Anand (verified owner) –

The machine came a few days earlier than stated. Very well packaged and the installation also went smoothly. After I executed the commands and calibrated the device, everything went as it should and the machine correctly found the position of the laser head. I hope that it will remain stable in the future and that the values will remain as it is calibrated. Everything works correctly I am really impressed with the performance of the machine and the results of the laser work.

Fatima Hussain (verified owner) –

I am a beginner and this laser engraver is equipped with everything I need. I USED GBRL SOFTWARE WITH A MAC SYSTEM AND THE CONNECTION WAS EASY. When cutting wooden blocks, I find it as easy as carving planks. And the effect is not bad, it is a good laser machine.

Gajaanan Pandey (verified owner) –

I did find that there was some smell while using it and found it would be better to use this engraver in a ventilated area. I think it should be necessary to buy another air assist to direct the airflow to the outside, the effect will be better!

Minu tripathi (verified owner) –

I am very satisfied with the engraving machine, I am a beginner and would like to familiarize myself with this equipment. It definitely fits the purpose. Looking forward to the effect!

Devraj Saxena (verified owner) –

Vir Chadha (verified owner) –

Very nice machine. With Lightburn very easy to work with it.

Shrut Mallhotra (verified owner) –

Naman Anand (verified owner) –

Perfect machine, well packaged, great engraving and cutting, worth buying!

Indu Jha (verified owner) –

I am a beginner and this laser engraver is equipped with everything I need. I USED GBRL SOFTWARE WITH A MAC SYSTEM AND THE CONNECTION WAS EASY. When cutting wooden blocks, I find it as easy as carving planks. And the effect is not bad, it is a good laser machine.

Sushama Sahani (verified owner) –

Very fast shipping, arrived quicker than I thought, everything in perfect condition, no damage and complete with accessories. I have tested the machine and everything works fine. This machine is really nice, I love it. I will recommend it to my friends!

GudduPathak (verified owner) –

Equipped with detailed assembly instructions, making assembly very easy to complete in 30 minutes. This laser machine is also suitable for inexperienced users. I am very satisfied!

Tenzin Chadha (verified owner) –

I did find that there was some smell while using it and found it would be better to use this engraver in a ventilated area. I think it should be necessary to buy another air assist to direct the airflow to the outside, the effect will be better!

Sangita Verma (verified owner) –

I am very satisfied with the engraving machine, I am a beginner and would like to familiarize myself with this equipment. It definitely fits the purpose. Looking forward to the effect!

Tanaya Anand (verified owner) –

Equipped with detailed assembly instructions, making assembly very easy to complete in 30 minutes. This laser machine is also suitable for inexperienced users. I am very satisfied!

Mangesh Kohli (verified owner) –

Very fast shipping, arrived quicker than I thought, everything in perfect condition, no damage and complete with accessories. I have tested the machine and everything works fine. This machine is really nice, I love it. I will recommend it to my friends!

Devdan Apte (verified owner) –

Easy assembly, directions were very easy to follow. Download light burn and easy to setup. Tested it out and did my Sasquatch for my cutting boards.

Kaia Grover (verified owner) –

Fast shipping and perfectly packaged. The laser machine is of high quality, operated according to the instructions, even beginners can master it quickly, everything is as described, it is great.

Devansh Jha (verified owner) –

This machine is the best I’ve ever seen, great quality, beautiful packaging, top notch engraving and cutting, thanks MechBlock!

Prabhavati Gupta (verified owner) –

Fast shipping and perfectly packaged. The laser machine is of high quality, operated according to the instructions, even beginners can master it quickly, everything is as described, it is great.

Natwar Karthick (verified owner) –

The machine came a few days earlier than stated. Very well packaged and the installation also went smoothly. After I executed the commands and calibrated the device, everything went as it should and the machine correctly found the position of the laser head. I hope that it will remain stable in the future and that the values will remain as it is calibrated. Everything works correctly I am really impressed with the performance of the machine and the results of the laser work.

Indranil Pandey (verified owner) –

I am very satisfied with the engraving machine, I am a beginner and would like to familiarize myself with this equipment. It definitely fits the purpose. Looking forward to the effect!

Satyabhama Singh (verified owner) –

Very nice machine. With Lightburn very easy to work with it.

Mina ben (verified owner) –

Easy assembly, directions were very easy to follow. Download light burn and easy to setup. Tested it out and did my Sasquatch for my cutting boards.

Kita Pandey (verified owner) –

The machine came a few days earlier than stated. Very well packaged and the installation also went smoothly. After I executed the commands and calibrated the device, everything went as it should and the machine correctly found the position of the laser head. I hope that it will remain stable in the future and that the values will remain as it is calibrated. Everything works correctly I am really impressed with the performance of the machine and the results of the laser work.

Tanaia Parihar (verified owner) –

This machine is the best I’ve ever seen, great quality, beautiful packaging, top notch engraving and cutting, thanks MechBlock!

Pinank Sethi (verified owner) –

I am a beginner and this laser engraver is equipped with everything I need. I USED GBRL SOFTWARE WITH A MAC SYSTEM AND THE CONNECTION WAS EASY. When cutting wooden blocks, I find it as easy as carving planks. And the effect is not bad, it is a good laser machine.

Aadidev Pandey (verified owner) –

Easy assembly, directions were very easy to follow. Download light burn and easy to setup. Tested it out and did my Sasquatch for my cutting boards.

Eravati Sinde (verified owner) –

Very nice machine. With Lightburn very easy to work with it.

Shashikant Sinha (verified owner) –

Perfect machine, well packaged, great engraving and cutting, worth buying!

Raghu Sharma (verified owner) –

Ejaya Philips (verified owner) –

I did find that there was some smell while using it and found it would be better to use this engraver in a ventilated area. I think it should be necessary to buy another air assist to direct the airflow to the outside, the effect will be better!

Devaki Ganguly (verified owner) –

Ramavati Ghosh (verified owner) –

Very fast shipping, arrived quicker than I thought, everything in perfect condition, no damage and complete with accessories. I have tested the machine and everything works fine. This machine is really nice, I love it. I will recommend it to my friends!

Anup Baisla (verified owner) –

Chinta Das (verified owner) –

Avadhesh Kaushik (verified owner) –

Bhasvan Gupta (verified owner) –

Deshal Apte (verified owner) –

Geeta Anand (verified owner) –

Swati Mehta (verified owner) –