Atomstack Hurricane 55W CO2 Laser Cutter Review

Introduction

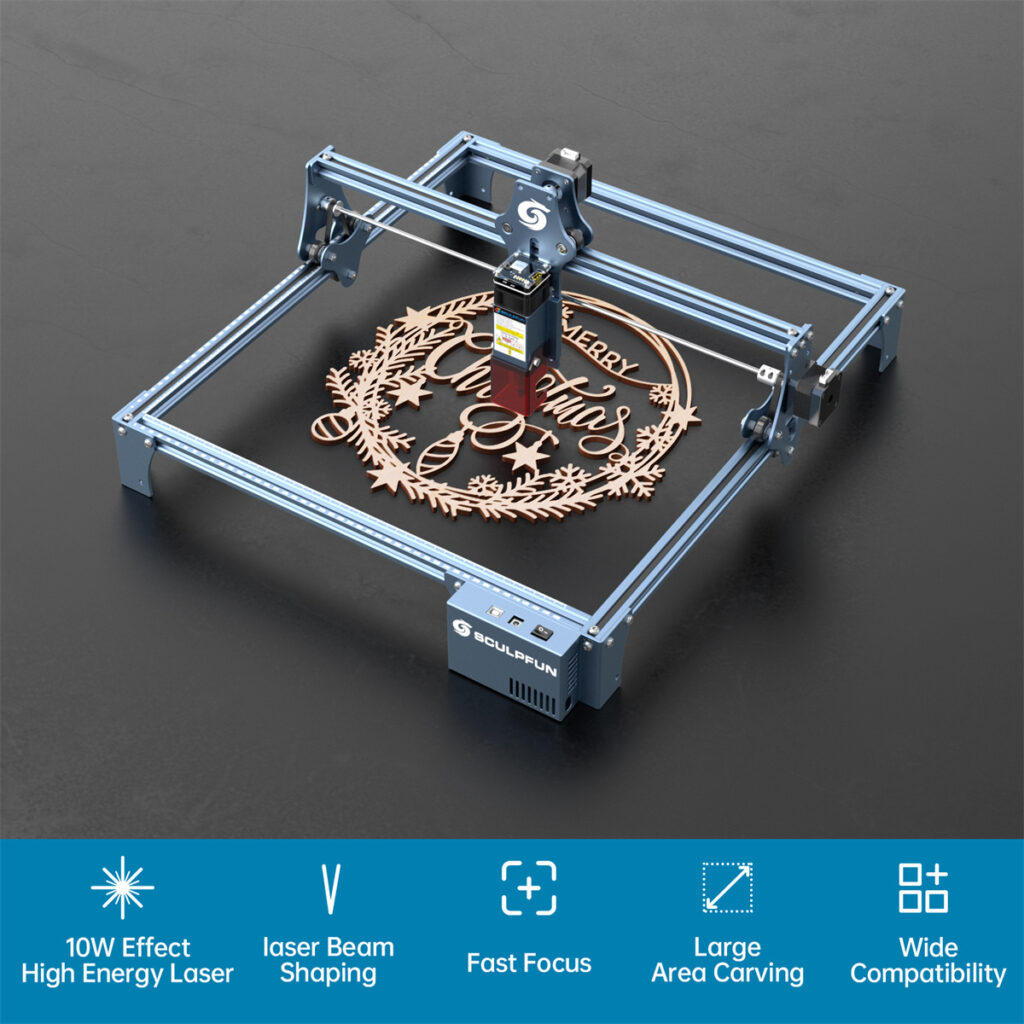

Atomstack Hurricane 55W CO2 desktop laser cutter is Atomstack’s new product launching in September 2024. Atomstack Hurricane laser cutter offers a competitive price which is an ideal upgrade for those looking to work more with acrylics or glass engraving. It can also engrave or cut various materials, including acrylic, wood, leather, glass, jewelry, rubber, paper, rock, etc. So this professional 55W desktop CO2 laser cutter is suitable for those people, such as woodworkers, event planners, sign makers, real estate agents, educators, entrepreneurs, small business owners, and crafts enthusiasts.

Unboxing and Setup

There’s not much to the Atomstack Hurricane’s packaging. The image below shows you what you get when you unpack the Atomstack Hurricane, including a total of 16 items inside the Atomstack Hurricane. It is worth noting that the package comes with a laser lens, two keys for the security lock, and a calibration card for the camera.

Setting up the Atomstack Hurricane is relatively simple, but it is important to remember to fill the tank with pure water first. According to the instruction guide, you need to fill the water in two times. The first time you fill the unit with 1000ml of pure water and then power on the Atomstack Hurricane, the pump will work causing the tank water level to become low. Finally, turn off the power of the device and continue to fill it with pure water a second time until the tank guidance level reaches the maximum mark line.

The Atomastck Hurricane CO2 laser cutter is equipped with a safety lock feature that requires the use of the safety lock key to open the safety lock clockwise before turning on the power. Then fit the exhaust dust hose and you are ready to start creating with LightBurn or Atomstack Studio software via USB connection.

Atomstack Hurricane Performance

Autofocus with one click

Atomstack Hurricane CO2 desktop laser cutter with a full enclosure design which is a denpendable laser cutter for home use. The autofocus feature is one of the reasons I like the Atomstack Hurricane. Although it is a professional desktop CO2 laser cutter, its user-friendliness also allows it to be a craft laser cutter tailor-made for the user.

The one-button autofocus feature makes the Atomstack Hurricane very easy to use. If you connect your machine using Atomstack Studio, you can click the autofocus button directly on the software.

55W CO2 laser & 600mm/s engraving speed

I did an engraving speed test to get a quick idea of the engraving speed and cutting efficiency of this Atomstack Hurricane CO2 laser cutter. As shown below, I divided the laser energy from 5% to 100% into 20 groups and the engraving speed from 60mm/s to 600mm/s into 10 groups.

The test result was not disappointing, the 55W laser power has very high efficiency in engraving materials. As you can see, with only 5% laser power, 3mm plywood can be engraved with a speed of 600mm/s leaving clear engraving marks on the wood. At 55% laser power and an engraving speed of 60mm/s, the Atomstack Hurricane has burned all of the 3mm plywood.

You will see later in the article how efficiently the 55W CO2 laser power and the maximum engraving speed of 600mm/s can be used for 3D engraving.

High cutting efficiency: 75mm/s cutting speed on 3mm plywood

Regarding cutting efficiency, the Atomstack Hurricane 55W laser power shows very efficient cutting speed. Take a 3mm plywood cutting test as an example, the cutting speed can reach 75mm/s under 100% laser power. This fast cutting speed allows users to complete large cutting tasks in a few minutes. Compared to other 20W diode laser cutters, the Atomstack Hurricane 55W cuts about 7 times faster.

Cutting 20mm pine in 1 pass

In the test of cutting 20mm pine, when I set 100% laser power and 5mm/s cutting speed, I could not cut 20mm pine in one go. But when I reduced the cutting speed to 2mm/s, the Hurricane could easily cut 20mm pine in one pass. So, I think with such powerful cutting ability, Atomstack Hurricane can meet almost all users’ cutting needs, whether you are a craft enthusiast, a woodworker, a professional small business owner, or an acrylic customization company, this device can meet your needs.

5.5 minutes efficient cutting of large-size plywood crafts

The Atomstack Hurricane CO2 Desktop Laser Engraver has an engraving area of 500mm*300mm, and with its powerful 55W CO2 laser power it can cut large areas with high efficiency. For laser cutting enthusiasts like me, I can cut large-size wooden crafts in one go. For example, I control the Hurricane to cut 300 mm*300 mm 3mm plywood in LightBurn software to make a dinosaur toy.

The cutting parameters are 100% laser power, 40mm/s cutting speed, and the final cut takes about 5.5 minutes to complete. In fact, it can be done faster because the previous cutting test can be known, Atomstack Hurricane can cut 3mm plywood at 75mm/s cutting speed. If you cut this dinosaur block with 3mm plywood at 75mm/s cutting speed, you should be able to finish the cut in 3 minutes. This is a very efficient job and I love it!

Image mode engraving on wood testing

I’m still using LightBurn software to control the Atomstack Hurricane to engrave images on plywood. The image engraving mode is one of the ways to test the engraving quality of a laser engraver. Of course, when engraving different images, different image engraving parameters may need to be adjusted to get the best engraving results.

In the case of my engraving of the Black Myth WuKong photos, to get a more satisfactory engraving result, I tried several times with different photo parameters before I finally set the engraving parameters for the engraving as shown in the picture below. Atomstack officially recommended choosing Stucki image mode when image engraving.

The parameters when I engraved the first Black Myth WuKong image were: line Interval 0.05mm, Contrast 0, Brightness 25, Gamma 1.2, and Stucki image mode. The engraving speed is 400mm/s, laser power is only 6%.

But when I engraved the second Black Myth WuKong photo, to achieve better engraving results, I needed to re-adjust the parameters of the image, such as Line Interval to 0.05mm, Contrast to 2, Brightness to 45, Gamma 1.25, but the image mode still needs to be Stucki. The engraving speed is 400mm/s and the laser power is reduced to 5%.

Black Myth WuKong-2 parameters

The final engraving results for these two images are shown below and I am very happy with them. Perhaps by continuing to adjust the picture engraving parameters I can do better. What I want to say here is that image engraving will not always use the same parameters, different images need to be adjusted to different engraving parameters to achieve a better performance. If you are using a laser engraving machine to engrave images with poor results, you may need to readjust the parameters first.

Compatible with all acrylics

The great thing about a CO2 laser cutter is that it can engrave and cut all colors of acrylic, including clear acrylic. That’s why the Atomstack Hurricane Desktop CO2 Laser Cutter is perfect for those with acrylic customization needs.

I used clear acrylic to customize a 300mm * 200mm size welcome sign for my studio. As you can see in the picture below, I am very satisfied with the result! Engraving clear acrylic parameters: engraving speed is 400mm / s, and laser power is 20%. Cutting this 3mm thickness of clear acrylic parameters: cutting speed is 20mm / s and 100% laser power. All processes are completed in about 10 minutes, with very high efficiency.

I have complete confidence in the Atomstack Hurricane 55W CO2 desktop laser cutter to cut acrylic because a 55W CO2 laser cutter can usually cut 20mm thickness of acrylic in one pass. So my only concern is whether the Atomstack Hurricane can achieve a better image engraving result on black acrylic.

As you can see below, I used the Atomstack Hurricane to engrave the third image of Black Myth WuKong on black acrylic. In the LightBurn software engraving parameters are: Stucki Image mode, Line Interval of 0.04mm, Contrast of 2, Brightness of -11, Gamma for 0.4, open the Negative Image function, the engraving speed of 600mm / s, laser power of 15%!

The LightBurn software estimated that it would take 40 minutes to complete the engraving, but in fact, it only took 25 minutes. Atomstack Hurricane image engraving on black acrylic is still good, but the texture of the image is not fine enough, which may be related to the Hurricane is only compatible with Stucki image mode. In terms of image engraving on black acrylic, I’m currently most satisfied with the xTool F1 Ultra.

Leather customized engraving

If you are a small craft business owner, you may need to customize some leather products for your customers. Here I have also tried for you using Atomstack Hurricane cut and engraved leather material. Of course, Atomstack Hurricane is compatible with many materials, leather is just one of them.

The engraving parameters for leather can be set to 400mm/s engraving speed and 20% laser power. For example, I personalized the engraving of a leather wallet using this engraving parameter. For engraving and cutting a 3mm thick leather round badge, the engraving parameters remain the same as for the leather wallet and the cutting parameters are 13mm/s cutting speed and 100% laser power.

The engraving results of the two leather products are shown below. I am very satisfied with it.

Camera calibration in Atomstack Studio

The Atomstack Hurricane has a high-definition camera to assist in engraving or cutting positioning. I needed a more complicated camera calibration process and had trouble using the LightBurn software. So I gave up using the LightBrun software to enable the camera engraving positioning feature. Instead, using the Atomstack Studio software became much easier.

Open Atomstack Studio and select the correct device (Atomack Hurricane) to connect it. At this point, the engraving positioning function is ready to use, but a camera calibration is recommended for more accurate engraving positioning. The calibration process is very simple, follow the instructions in two steps.

First: Place a flat piece of material larger than 300mm * 300mm and allow the Atomstack Hurricane to engrave the appropriate markings. Second: Take a picture and let the Atomstack Hurricane analyze the positioning data.

High engraving positioning accuracy: only within 0.8mm position error

After completing the camera positioning calibration on the Atomstack Studio software, I then began testing the accuracy of the engraving positioning. First, I engraved a large rectangle and circle on 3mm plywood and then captured it in Atomstack Studio as shown below.

To verify the accuracy of the Atomstack Hurricane’s engraving positioning, I drew four small rectangles at each of the four corners of the large rectangle and a rectangle inside the circle. These patterns all fit accurately with the inner edges of the large rectangle and the large circle. Just as shown below.

Each pattern was then engraved on the plywood by setting the appropriate engraving parameters. The engraving results are shown below. To the naked eye, the engraving positioning of the Atomstack Hurricane is quite accurate.

After closer inspection, I found that the actual engraved pattern was slightly off in the Y direction compared to the position in the software. On the software, the small rectangles I drew fit the inner edges of the large rectangles, but when I actually engraved the small rectangles, the edges of the small rectangles were slightly off in the Y-direction, while the X-direction was well aligned. Just as shown below.

To find out how much the actual engraving positioning was deviating, I clicked on the camera function on the software, recaptured the engraved image, and then zoomed in to compare it to the pattern on the software. Using the ruler function on the software, I was able to measure the deviation in the Y-axis direction: 0.8mm. Just as shown below.

My Atomstack Hurricane only has a maximum positioning error of 0.8mm in the Y-axis direction on 3mm plywood. I did these tests not to bash it, but because I wanted to know more about its characteristics, and there is a tolerance for error in any machine. With such a small positioning error, I totally accept it. In practical engraving cases, the Atomstack Hurricane’s camera engraving positioning works quite well and completely eliminates the hassle of manual engraving positioning.

Fast-speed 3D engraving on wood

The Atomstack Hurricane makes 3D engraving on wood easy thanks to its powerful 55W CO2 laser. If you are using the Atomstack Studio software, 3D engraving becomes even easier. The Atomstack Studio software provides many patterns that can be 3D engraved directly.

One of the benefits of using Atomstack Studio is that you don’t have to manually test the engraving parameters, as it provides the ability to set the correct engraving parameters for different materials automatically.

In this 3D engraving project, the engraving speed was 200mm/s, the laser power was 100%, and the perfect embossing engraving was completed in 12 minutes.

The Atomstack Hurricane is etched so deeply into the 10mm pine, about 4mm deep, that the pattern is very three-dimensional and lifelike. As you can see below.

Batch engraving coated metal with camera positioning

Atomstack Huricane can still engrave effectively on coated metals. I can even do batch engraving easily thanks to the HD camera engraving positioning feature.

As you can see in the picture below, the pattern falls exactly on the aluminum sheet according to the position preset in the software.

Pros and Cons

Pros

- 55W CO2 laser power

- 600mm/s

- Compatible for all acrylics, including clear acrylic

- Autofocus

- 500*300mm large engraving area

- Fully enclosure

- Efficient tasks handling

- All-around safe protection

- Excellent in 3D engraving

- Accurate positioning with HD camera

- Good engraving results on wood

- Low working noise

Cons

- Heavy

- Unsupported WIFI connection

Specifications

| Product model | Atomstack Hurricane |

| Machine Size | 102*64*23cm |

| Laser Power | 55W CO2 Laser |

| Laser Wavelength | 10.6μm |

| Engraving Area | 500*300mm 800*500mm with conveyor belt |

| Engraving speed | 600 mm/s |

| Autofocus | Yes |

| Camera | 5MP high-definition |

| Engraving Positioning | Yes |

| Air-assist | Built-in |

| Working Noise | 50 db |

| Safety Protection | Fire detection; tilt detection; Auto-extinguishing; Safety lock; Emergency stop; Lip-open detection; |

| Compatible material | All acrylics, wood, leather, glass, jewelry, rubber, coated metals, denim, paper, rock, and many others |

| Software | LightBurn/Atomstack Studio |

| Connection | USB |

Conclusion

The Atomstack Hurricane 55W desktop CO2 laser cutter is a worthy investment. It’s auto-focus and precise engraving positioning features allow users to be more efficient in handling heavy custom engraving tasks. I especially appreciate its 3D engraving capabilities, acrylic compatibility, and image engraving quality. If you are a professional laser engraving group that makes a living by laser engraving, the Atomsatck Hurricane is one of the investment devices available to you, especially for acrylic craft producers. You may ask if the Atomstack Hurricane is suitable for personal hobby use. Then what I would say is that it is certainly a good option if you can live with its large size and relatively expensive price.